Precision CNC Milling & Large CNC Machining

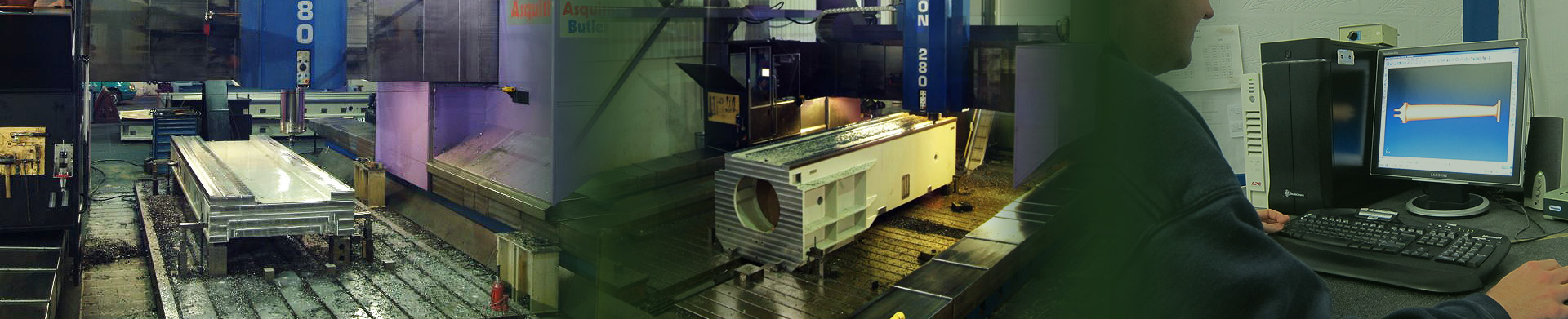

At Forth, our subcontract machining facility is equipped with two state-of-the-art Asquith Butler CNC Gantry Milling machines, housed within an interconnected, temperature-controlled manufacturing cell. This advanced setup enables us to deliver both large CNC machining and precision CNC milling services with exceptional accuracy and consistency.

Our gantry milling capabilities support component machining up to 9.5 metres in length, 4.5 metres in width, and 1.7 metres in height, ideal for large-scale, high-tolerance projects.

Each CNC machine is regularly laser-calibrated in-house, ensuring stringent control over positional accuracy across all linear axes. This scheduled calibration meets the demanding tolerances required by industries where precision is non-negotiable.

Featuring up to 5-axis machining, Fanuc 15i-M control systems, and RMP60 Renishaw radio probes, our gantry mills offer unmatched versatility and performance. This allows us to confidently handle complex and custom machining jobs across a broad range of applications.

Forth's extensive experience spans the machining of diverse component constructions—including forgings, castings, fabrications, composite structures, and raw plate materials weighing up to 20 tonnes. We are highly proficient in working with mild steel, stainless steel, aluminium, titanium, cast iron, and high-speed steel.

With a long-standing commitment to excellence, Forth has refined the craft of ultra-high precision CNC milling, delivering parts with exceptional straightness, flatness, and squareness. This dedication positions us as a trusted partner to some of Europe’s most prestigious machine tool manufacturers.